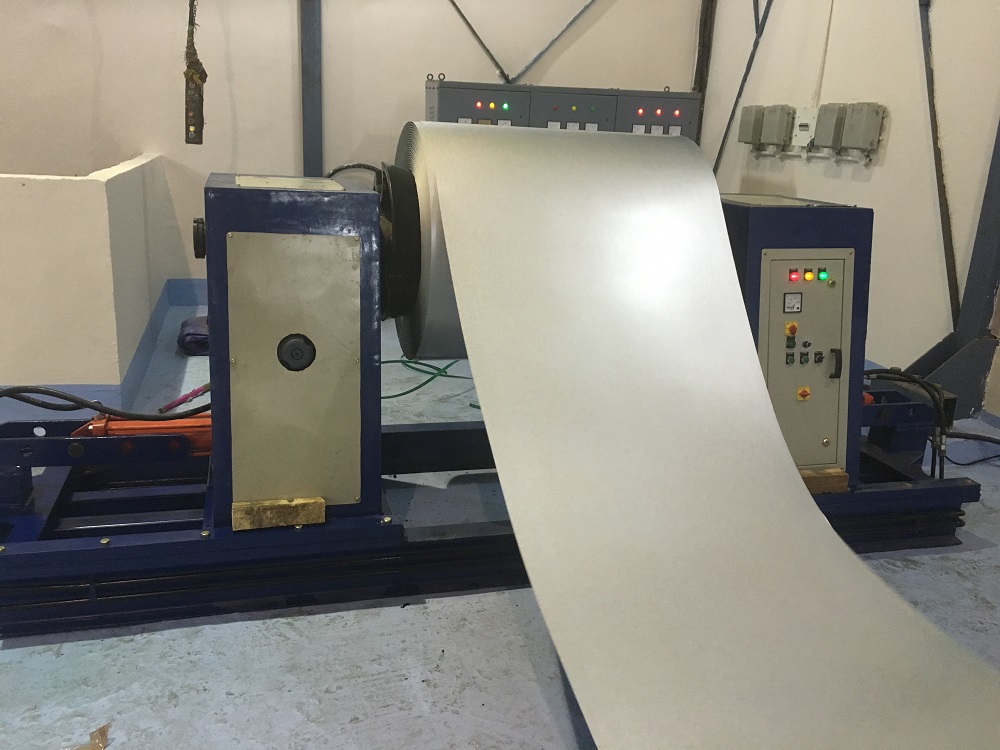

Decoilers

Sheet metal decoilers are critical pieces of equipment in the metalworking industry, enabling the safe and efficient handling of large and heavy sheets of metal. This article will delve into everything you need to know about sheet metal decoilers, including their purpose, functionality, and factors to consider when purchasing one.

What is a Sheet Metal Decoiler?

A sheet metal decoiler, also known as a metal uncoiler or decoiler, is a machine used to unwind and unroll coils of sheet metal. It is commonly used in the metalworking industry to feed sheet metal into other machines, such as stamping presses, roll formers, and cutting machines.

Types of Sheet Metal Decoilers

Several types of sheet metal decoilers are available on the market, including motorized, manual, hydraulic, and combination decoilers. Motorized decoilers are the most common and equipped with a motor that drives the spindle. Manual decoilers are operated by hand and generally used for smaller coils of sheet metal. Hydraulic decoilers use hydraulic cylinders to control the tension on the sheet metal and are used for larger and heavier coils. Combination decoilers can handle both light and heavy coils and may be equipped with additional features, such as coil cars and peeler tables.

Factors to Consider When Choosing a Sheet Metal Decoiler

When choosing a sheet metal decoiler, several factors should be taken into consideration, including the coil weight and size, material type, coil width, production requirements, and safety features. The decoiler should be capable of handling the weight and size of the coil of sheet metal that it will be unwinding, and it should be appropriate for the material that will be used. The decoiler should also accommodate the width of the sheet metal it will be unrolling, and the production requirements should be considered to determine the necessary speed and capacity of the decoiler. Additionally, it is essential to choose a decoiler equipped with safety features, such as guards and emergency stops, to ensure the safety of workers.

FAQs

1.Q: What is the maximum weight capacity of a sheet metal decoiler?

A: The maximum weight capacity of a sheet metal decoiler varies depending on the type and model of the machine but typically ranges from a few hundred pounds to several thousand pounds.

2.Q: What is the difference between a motorized decoiler and a hydraulic decoiler?

A: Motorized decoilers are the most common type and equipped with a motor that drives the spindle, while hydraulic decoilers use hydraulic cylinders to control the tension on the sheet metal. Hydraulic decoilers are typically used for larger and heavier coils.

3.Q: What is the maximum coil width that a sheet metal decoiler can handle?

A: The maximum coil width that a sheet metal decoiler can handle varies depending on the type and model of the machine but typically ranges from a few inches to several feet.

4.Q: What is the role of sensors in a sheet metal decoiler?

A: Sensors in a sheet metal decoiler monitor the tension on the sheet metal and adjust the spindle’s speed accordingly to prevent the sheet metal from becoming too loose or tight.

5.Q: Can a sheet metal decoiler be used for other materials besides metal?

A: No, sheet metal decoilers are designed specifically for use with sheet metal and may not be suitable for use with other materials.